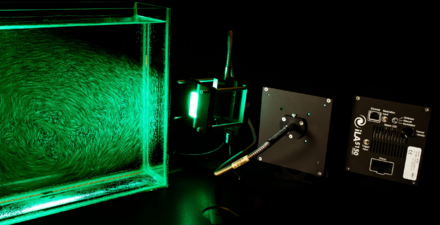

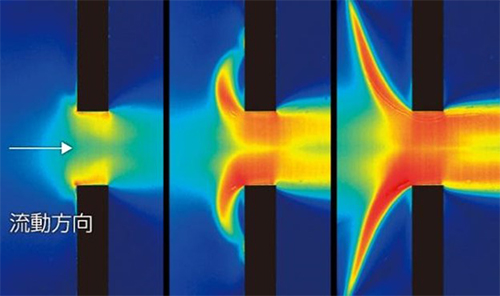

In collaboration with ILA_5150 GmbH, a leader in Particle Image Velocimetry (PIV) solutions, we offer advanced systems that enable real-time visualization of fluid dynamics.

Innovations in Particle Imaging: Real-Time Visualization of Fluid Dynamics

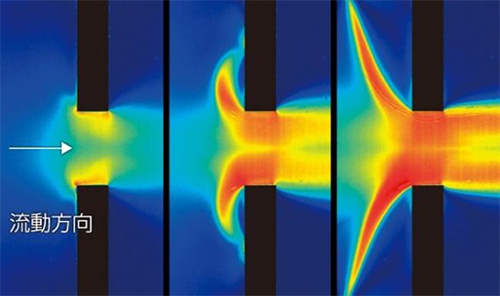

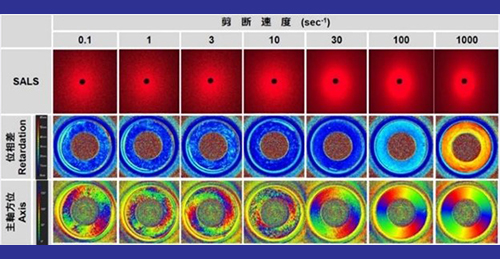

Understanding fluid behavior is crucial across various scientific and engineering disciplines, from aerodynamics to biomedical engineering. Traditional methods of studying fluid flow often involve complex calculations and indirect measurements, which can be time-consuming and less accurate. ILA_5150’s PIV technology revolutionizes this process by providing direct, real-time visualizations of fluid motion.

How ILA_5150’s PIV Technology Works

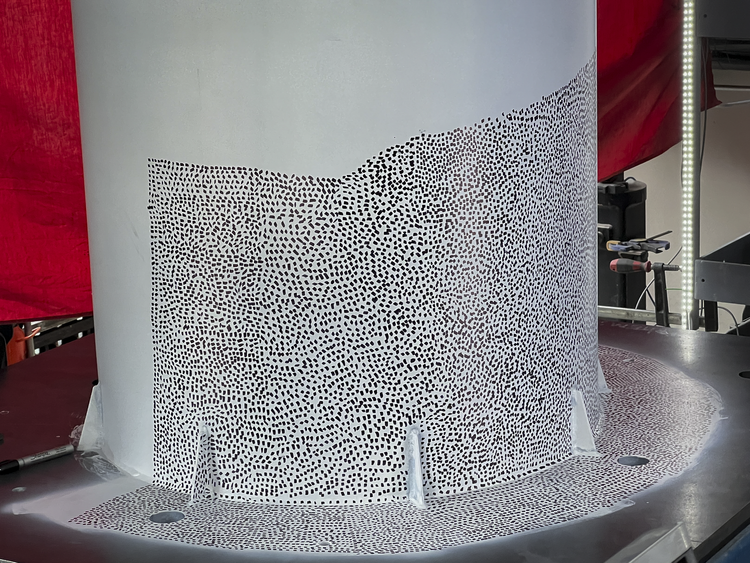

PIV is an optical method that captures the movement of seeded particles within a fluid to map out the velocity field. The basic setup includes:

- Light Source: Typically, a laser or LED system that illuminates a thin plane of the fluid.

- Optics: Components that shape the light into a sheet, illuminating only the region of interest.

- Cameras: High-speed cameras that capture sequential images of the illuminated particles.

- Synchronizer: A device that precisely coordinates the timing between the light source and the cameras.

- Seeding Particles: Microscopic particles introduced into the fluid to act as tracers.

- Software: Advanced algorithms that analyze the captured images to calculate velocity vectors and generate visualizations.

This setup allows researchers to obtain instantaneous velocity measurements and related properties in fluids, providing a comprehensive understanding of flow dynamics.

Applications and Benefits

ILA_5150’s PIV systems have been successfully implemented in various applications:

- In-Cylinder Flow Analysis: High-speed imaging of spray from multi-hole gasoline injectors was conducted within an optical engine at a repetition rate of 16 kHz, aiding in the development of more efficient combustion systems.

- Marine Research: Observing “marine snow” in challenging environments aboard research vessels, contributing to our understanding of oceanic particulate matter.

- Automotive Engineering: 2D-3C measurements in the wake of axial automotive fans to validate computational fluid dynamics (CFD) results, leading to improved cooling system designs.

By integrating ILA_5150’s PIV technology, researchers and engineers can visualize complex fluid interactions in real-time, leading to more accurate analyses and accelerated innovation. At Blink Technology, we are proud to offer these advanced PIV solutions, empowering our clients to push the boundaries of what’s possible in fluid dynamics research.

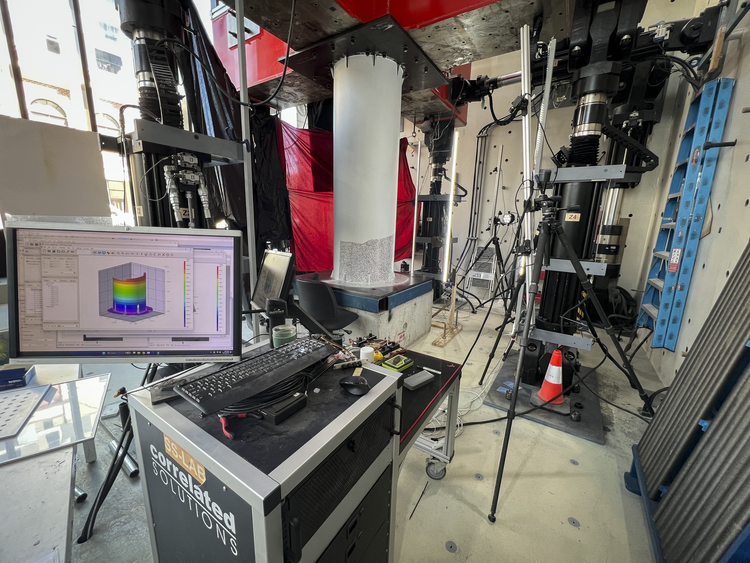

VIC Edu

VIC Edu