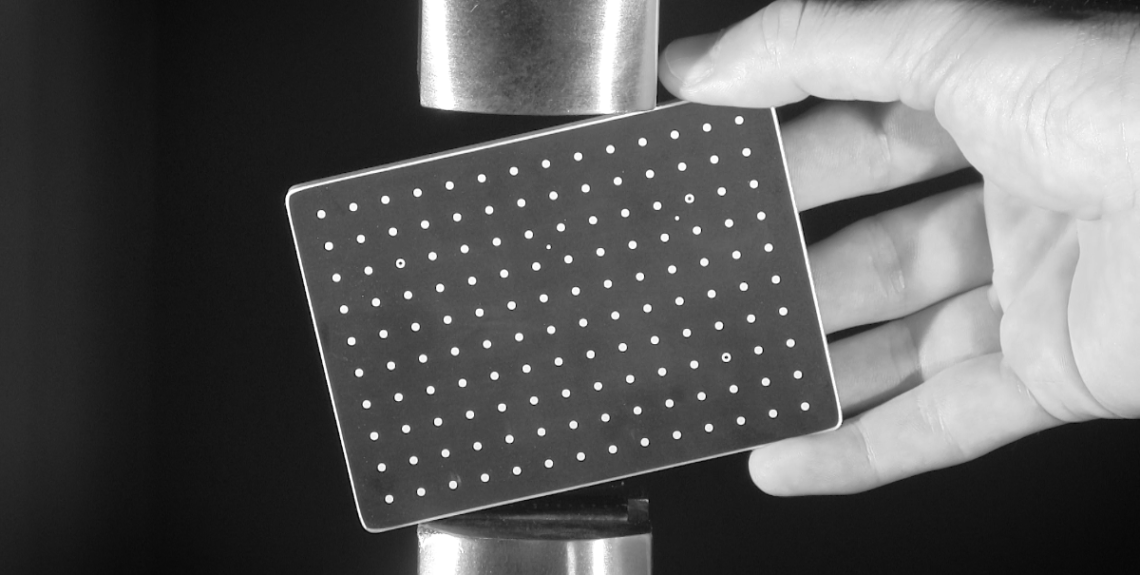

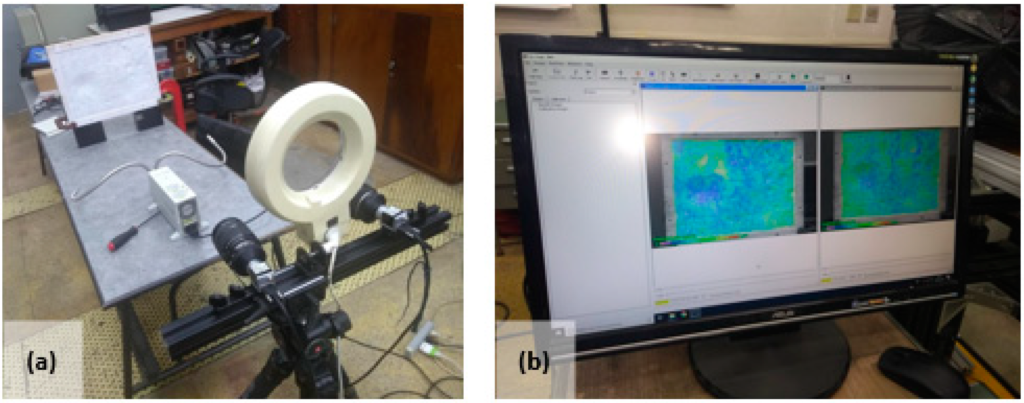

Successful digital image correlation requires accurate calibration. Correlated Solutions is proud to introduce an all-new set of laser-marked calibration targets with precision marker placement and improved contrast which provides more accurate stereo-camera calibration. This yields more consistent centroid extractions in VIC-3D and produces improved calibration scores. The end result is a more robust 3D digital image correlation system and improved accuracy in displacement and strain measurements.

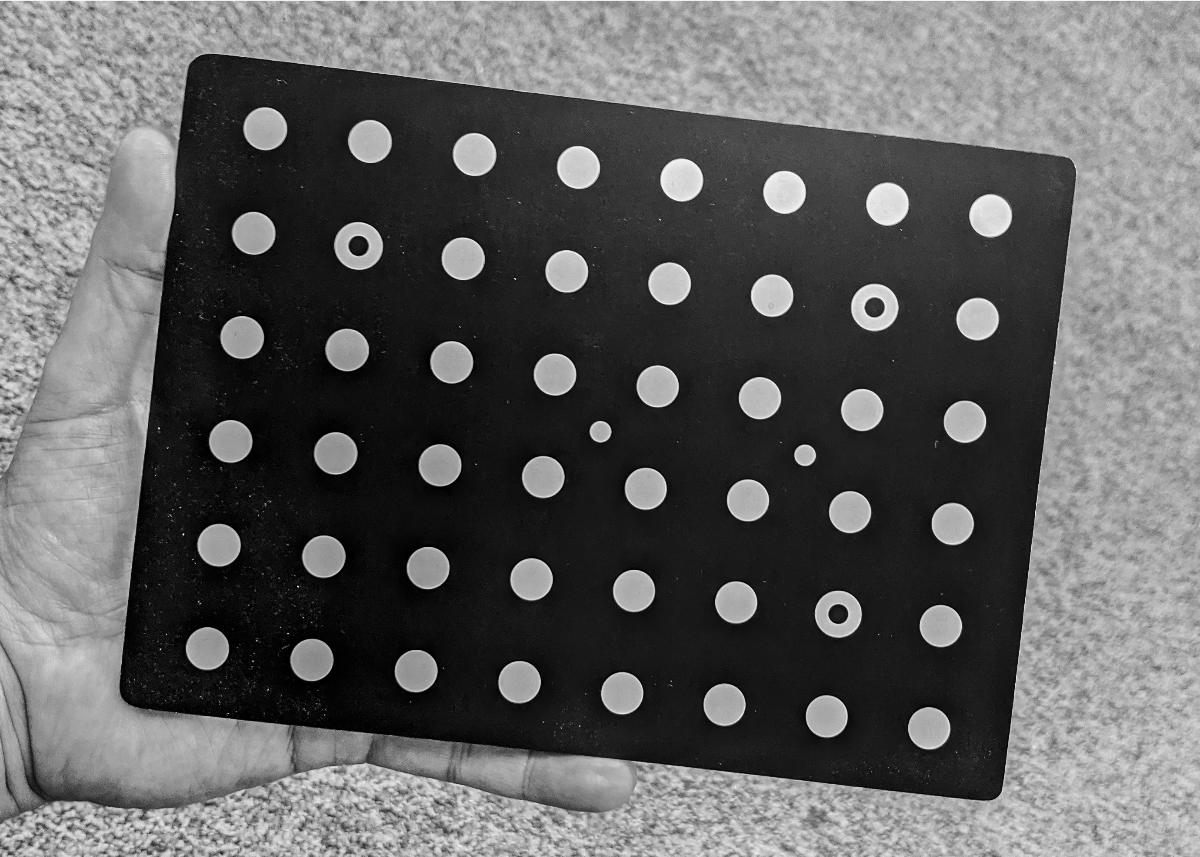

In addition to the new Calibration Target Kit, Correlated Solutions is also now offering low-resolution calibration targets for cameras with less than one megapixel in total resolution. This is common with high-speed cameras such as the Photron Fastcam NOVA when run at higher speeds. The targets have fewer and larger markers, which allows VIC-3D’s algorithms to locate the centroids with more accuracy and consistency, improving the overall stereo-calibration and analysis results.

VIC Edu

VIC Edu