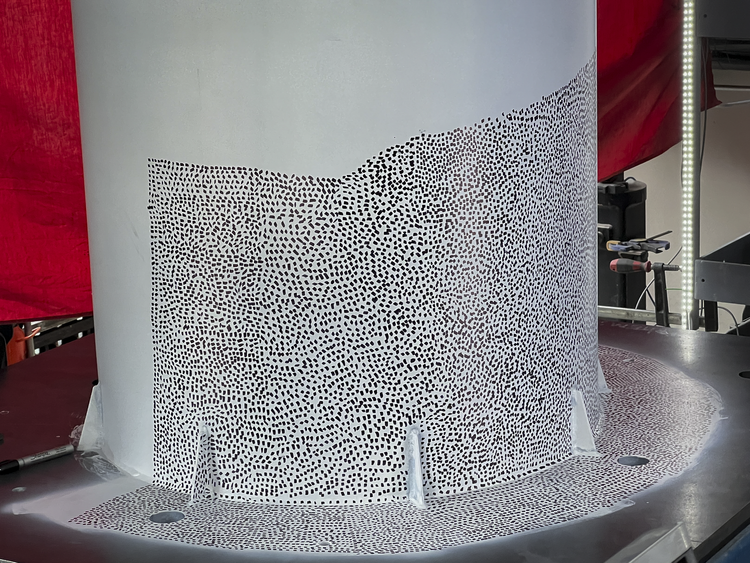

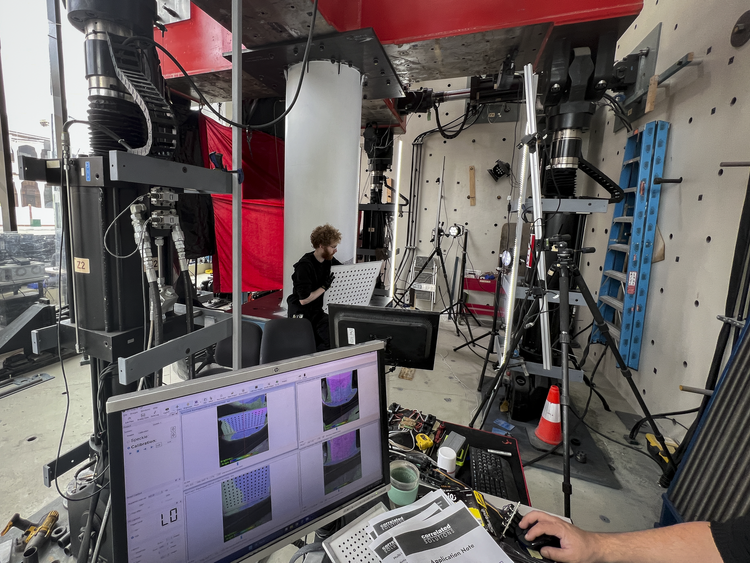

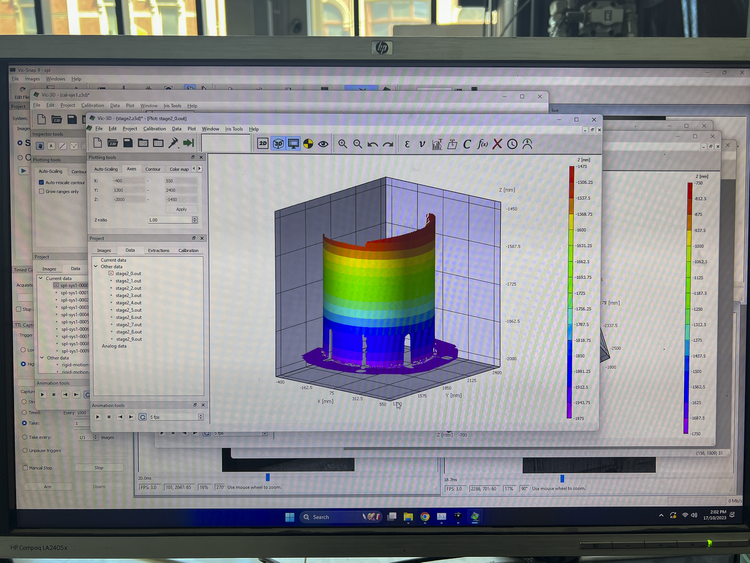

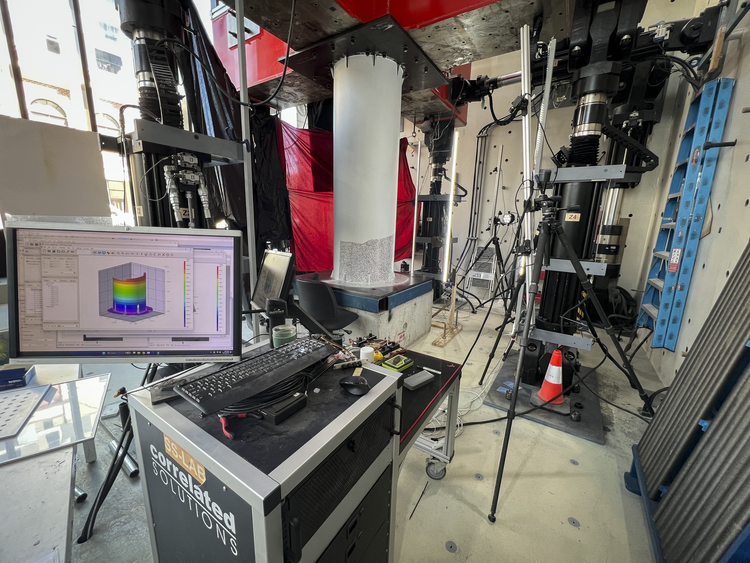

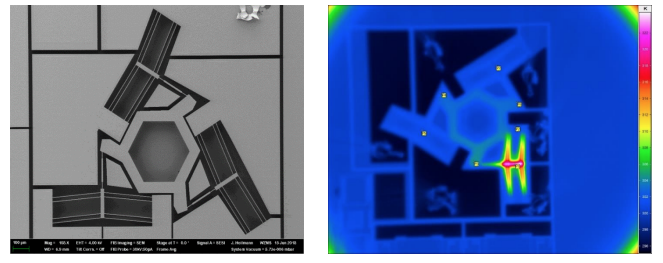

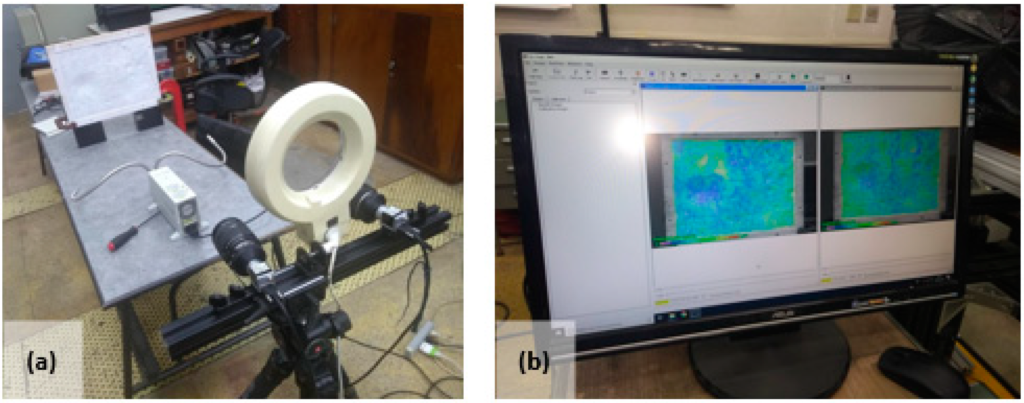

Correlated Solutions and Blink Technology Australia recently visited Kevin Nievaart and his team at Swinburne University of Technology’s Smart Structures Laboratory to assist in deploying the multi-system digital image correlation registration which combines data from two or more VIC-3D DIC systems. This procedure provides a common coordinate system without any overlapping requirements and can dramatically reduce the effort and time needed to interpret and analyze deformation data.

When teams are working with tools like the impressive Multi-Axis Substructure Testing (MAST) System, streamlining workflows is paramount, and the VIC-3D Multi-System was the obvious answer for boosting the performance and research efficiency of the Smart Structures Lab. Special thanks to Kevin and his team for all the hard work. We can’t wait to see more results!

VIC Edu

VIC Edu