Adding new value to rheometers

with next generation of analysis through “polarization imaging”

This equipment can clarify material properties based on the molecular structure of polymers.

Recently, there is an increasing demand for detailed analysis of the change process of material structure for advanced control of viscoelasticity.

In this page, we will introduce a “structural analysis method using polarization imaging” that combines a rheometer and a high-speed 2D polarization camera to meet these needs.

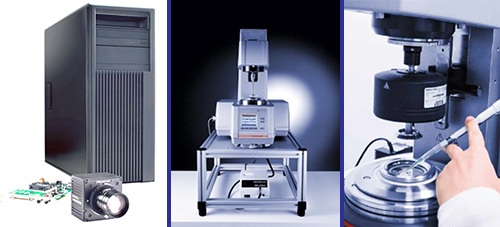

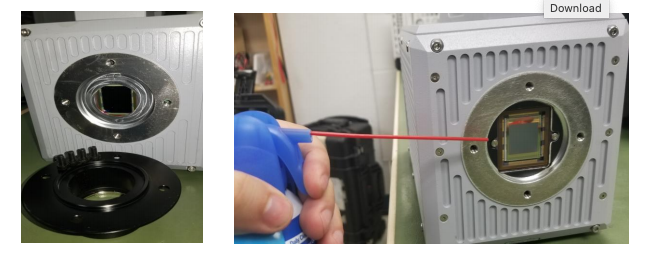

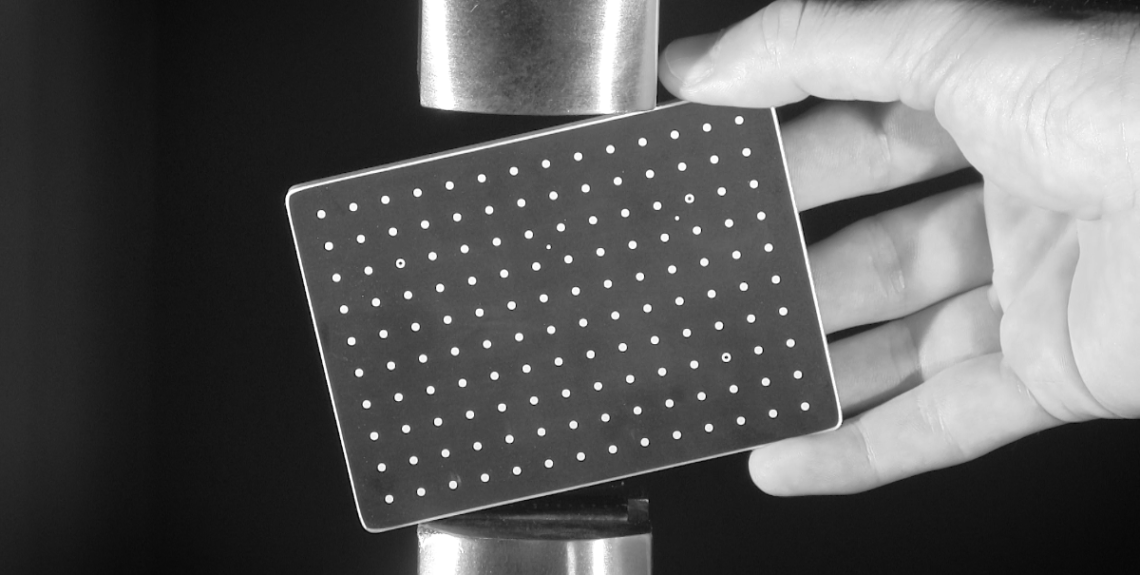

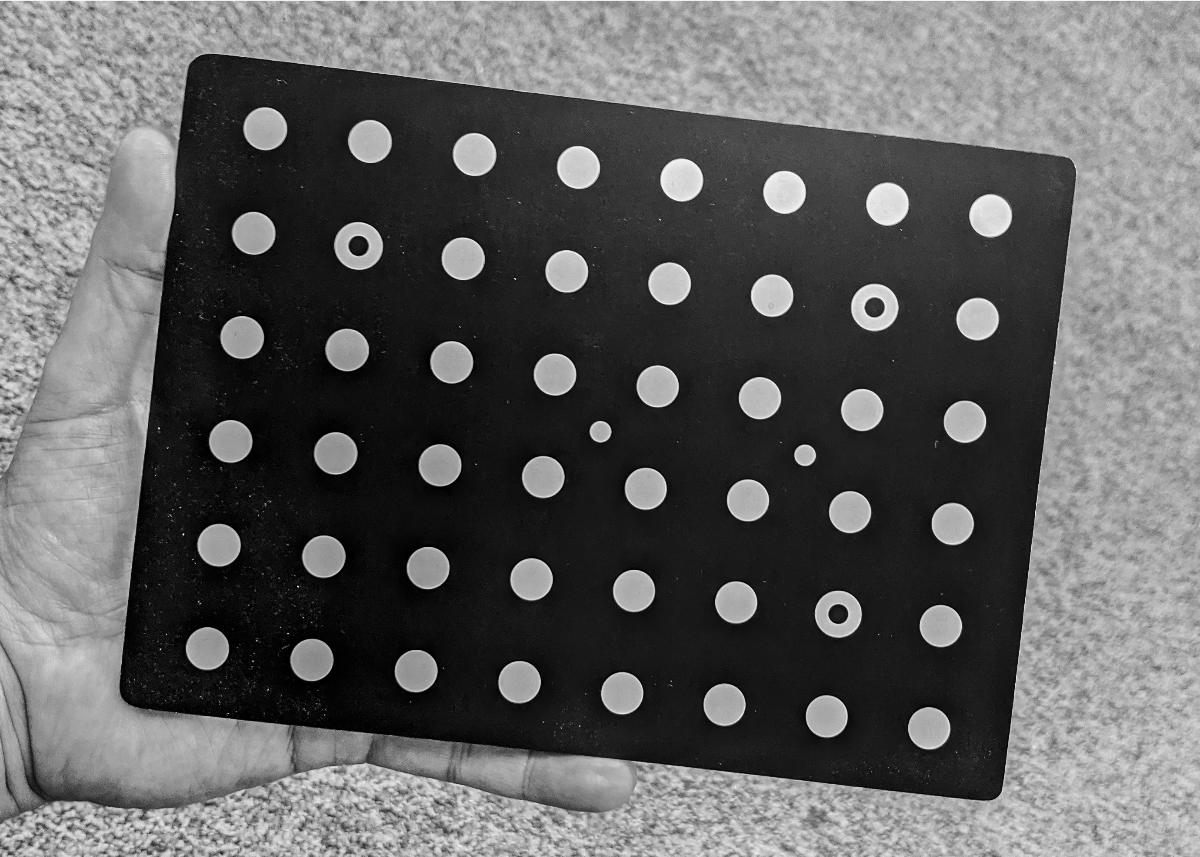

Polarization high-speed camera for viscoelasticity evaluation

Polarization high-speed camera and rheometer

*The rheometer is a product of Anton Paar

http://go.pardot.com/e/274612/en-products-crysta-pi-5wp-/hf2kn/589101049?h=kjns-AGZYWJ8UlPHU5oOHlQZDrDiY4wlHSject9SrK4

Feature

The high-speed polarization camera can quantify the polarization state in a single shot, and can track instantaneous changes in viscoelasticity due to its high-speed imaging performance.

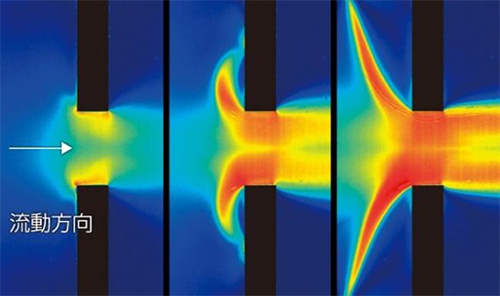

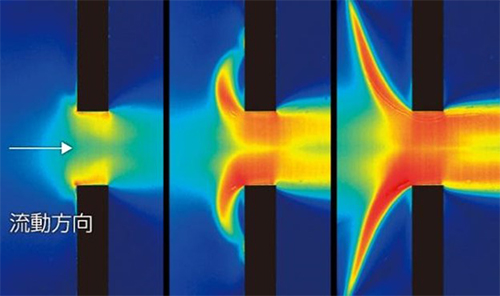

Capturing instantaneous orientation changes of polymer fluids

http://go.pardot.com/e/274612/en-case-case-853/hf2kr/589101049?h=kjns-AGZYWJ8UlPHU5oOHlQZDrDiY4wlHSject9SrK4

Video: http://go.pardot.com/e/274612/E-8lGrOyjYQ/hf2kv/589101049?h=kjns-AGZYWJ8UlPHU5oOHlQZDrDiY4wlHSject9SrK4

Measurement example – Dynamic structural change of cellulose nanofiber (CNF)

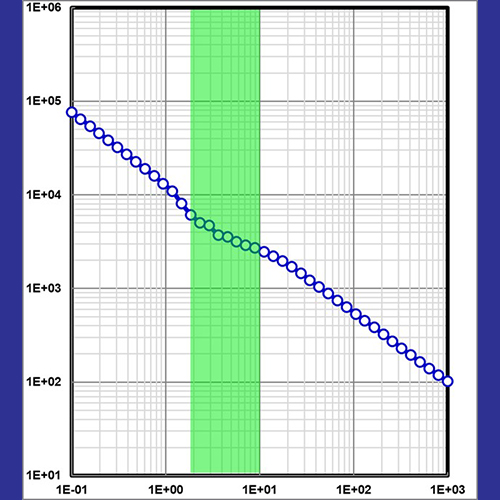

CNF has a three-dimensional network structure, but as shown in the viscosity curve below, it exhibits shear-thinning behavior in which viscosity decreases with shear rate. However, there is a viscosity plateau (green area) around ~10 sec-1.

Viscosity curve of CNF

What kind of structural changes occurred in this plateau?

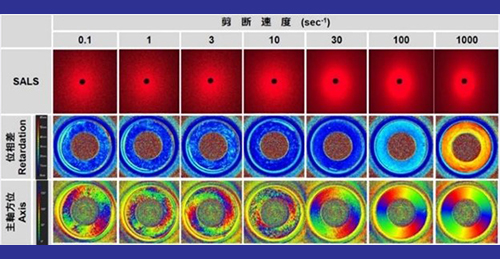

Looking at the scattering image of SALS (Small Angle Light Scattering) in the figure below, the shape changes from a circle to an ellipse as the shear rate increases. This corresponds to aggregates of fibers oriented in the direction of flow.

According to the orientation of the principal axis of the polarization image, the orientation of the fibers was spatially random before 10 sec-1, but after 10 sec-1 they suddenly oriented in the direction of flow, making them uniform in the radial direction within the channel. This confirms that it changed to a smooth state continuously.

Usually, if the viscosity curve is different from what we expected, we often suspect foreign matter contamination or that the equipment itself is somehow defective. In this study, we were able to gain a deeper understanding of the viscoelastic characteristics of CNFs by capturing instantaneous changes in the orientation of polymer fluids in combination with polarization imaging.

VIC Edu

VIC Edu