An InfraTec thermography automation solution supports the monitoring of one of the world’s largest solar tower power plants in the middle of the Atacama Desert.

Solar power plants usually suffer from the disadvantage that they only supply energy when the sun is shining during the day. CSP (Concentrated Solar Power) solar tower power plants are different: they charge a large thermal buffer storage during the day, which allows the continuous generation of electrical energy also at night‐time. One of these solar tower power plants recently went into operation in the middle of the Atacama coastal desert in Chile. It is the sunniest and driest desert on earth. The extreme climatic conditions prevailing in this region place high demands on the technology used there, including the eight thermographic cameras from InfraTec.

The power plant in Chile, named Cerro Dominador, comprises a 252‐metre‐high concrete tower with a cylindrical 360° solar receiver consisting of 16 panels surrounded by 10,600 movable mirrors arranged in concentric circles. The mirrors, known as heliostats, are controlled to reflect solar radiation directly onto the receiver’s absorber panels at the top of the tower. These panels, consisting of a tubular structure, have molten salt flowing through them, which is heated to over 600 °C by the concentrated solar radiation. The hot molten salt is led through pipes to the ground, where it generates steam via a heat exchanger that in turn is used to drive a steam turbine to generate electricity. Since the liquid salt can be stored in large insulated tanks for up to 17 hours, it is possible for this solar tower power plant to generate electricity continuously.

Temperature monitoring over long distances with infrared cameras

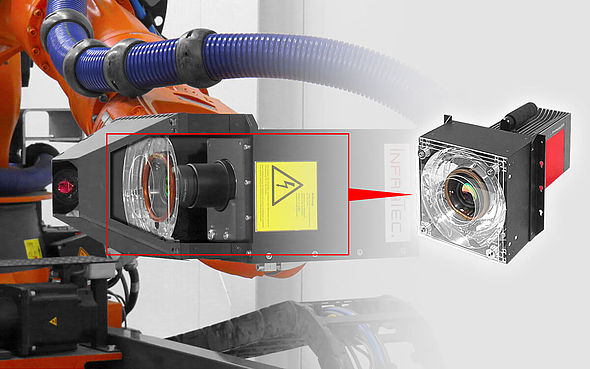

The solar tower receiver’s absorber panels can heat up to 800 °C and are monitored fully automatically around the clock by a total of eight infrared cameras from the InfraTec VarioCAM® HD series. Arranged in a circle around the tower, they form the backbone of InfraTec’s Solar Power Tower Check (SPTC) automation solution. Because of the VarioCAMs high resolution combined with a large field of view each panel can be redundantly monitored by two independent cameras resulting in much higher availability. The temperature and its distribution across the absorber are determined in real time and enable optimal control of the heliostats. At the same time, the permanent thermographic temperature monitoring provides life insurance for the billion‐dollar project: disastrous damage, caused for example by the overheating of individual panels or panel areas, is reliably avoided. The measurement of the panel temperatures also enables a precise analysis of the energy efficiency and supports the setting of optimal operating parameters for power generation. The goal is always to achieve the most homogeneous temperature distribution possible over the entire surface.

Automated monitoring under extreme conditions

Despite the extreme environmental conditions and the great distance to the measurement object, the SPTC system delivers pixel‐precise measurement results. This is made possible, among other things, by an infrared telephoto lens specially developed for this application, which has been adapted to the general conditions and enables very accurate temperature measurement even with strongly fluctuating ambient temperatures. The lens is precisely aligned with the receiver and only images the receiver in full format. As a result, the camera’s detector is automatically protected from direct irradiation by the sun and cannot be subject to lateral fatigue. The special design of the camera and lens means that there is no need for cooling of the protective housing, which significantly reduces maintenance and ensures continuous operation. In addition, the housing has a special rail and latching system, which guarantees quick removal and installation without time‐consuming adjustment of the camera in the event of maintenance.

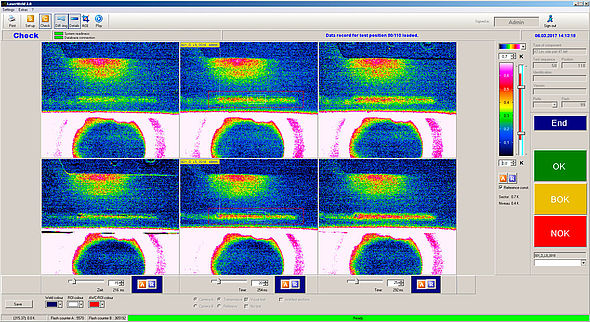

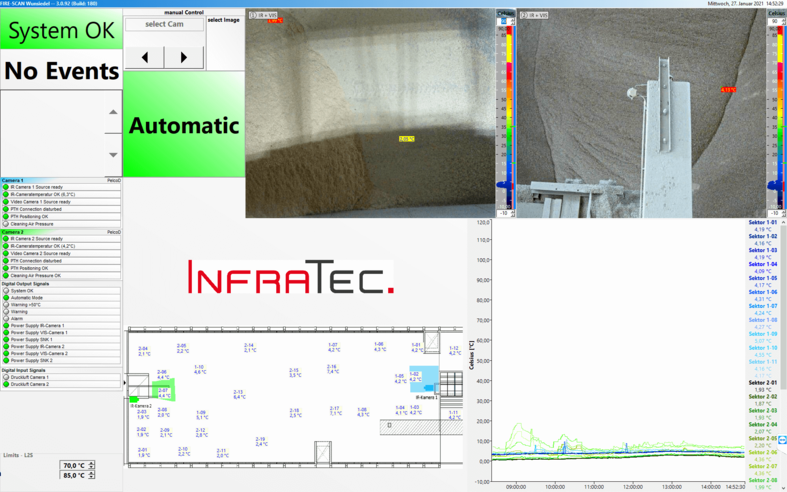

Everything in view with highly sophisticated software

This technology is supported by specially configured SPTC software that enables the evaluation of the measurement data and supports all operating regimes of the solar tower power plant. Furthermore, with the help of artificial intelligence, the software allows software‐based, highly accurate stabilisation of the infrared camera image to compensate for thermal and wind‐induced mechanical movements of the tower and to enable pixel‐precise image tracking during the operating period. Due to the equalised representation of the individual measurement areas on the absorber surface, inhomogeneities as well as hot and cold spots can also be easily identified visually.

VIC Edu

VIC Edu