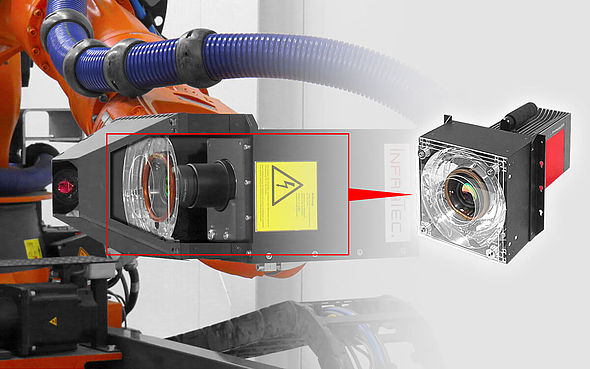

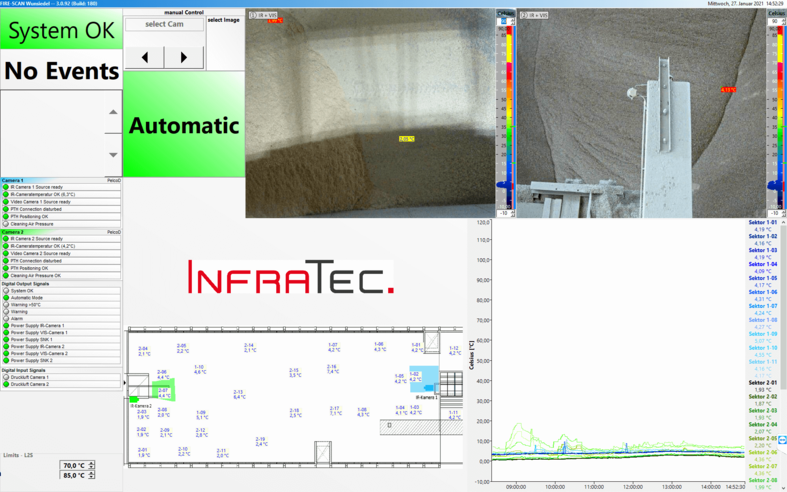

Using pulse thermography, WELD-CHECK enables you a quantitative assessment of the inspected welds. A special software algorithm analyzes the pulse-induced change in temperature in the tested joint and computes, based on its temporal course and geometric spreading, corresponding test results. These results are documented in a test report and provided in a format that can be used in your quality databases. This makes WELD-CHECK the ideal test system for automobile body assembly – both as an offline measuring unit as well as for in-line inspection.

Thermal imaging cameras of the high-end camera series ImageIR ® by InfraTec are essential components used in this system. Enabling a geometric resolution of up to (1,920 × 1,536) IR pixels, frame rates with some kHz and thermal resolutions below 0,015 K they provide the precise measurement basis for the reliable detection of even the smallest anomalies.

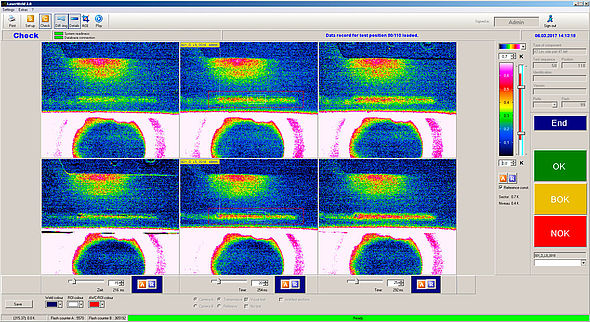

WELD-CHECK Software

- Different operating modes for Teach-In, testing and offline analysis

- Provision of all relevant information in testing mode with live, difference, evaluation and reference image

- Comprehensive representation of results

- Offline mode for parameterisation and evaluation of large datasets

- Flexible integration into the local system structure via universal interfaces and bus systems

VIC Edu

VIC Edu