Description

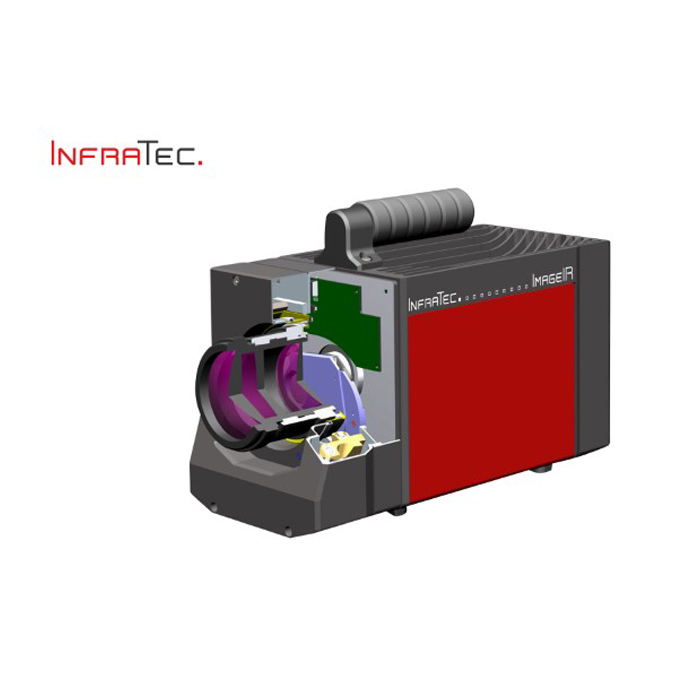

The high-end thermography systems of the product line ImageIR® are conceived for application with highest standards in the fields of research and development, non-destructive material testing and process monitoring. The modular outline allows for an individual system configuration and ideal adjustment of the performance data to the respective task.

Researchers and scientists, who depend on flexible infrared camera technology with maximum sensibility, accuracy, spatial resolution and speed, have a perfect solution available with the ImageIR® series.

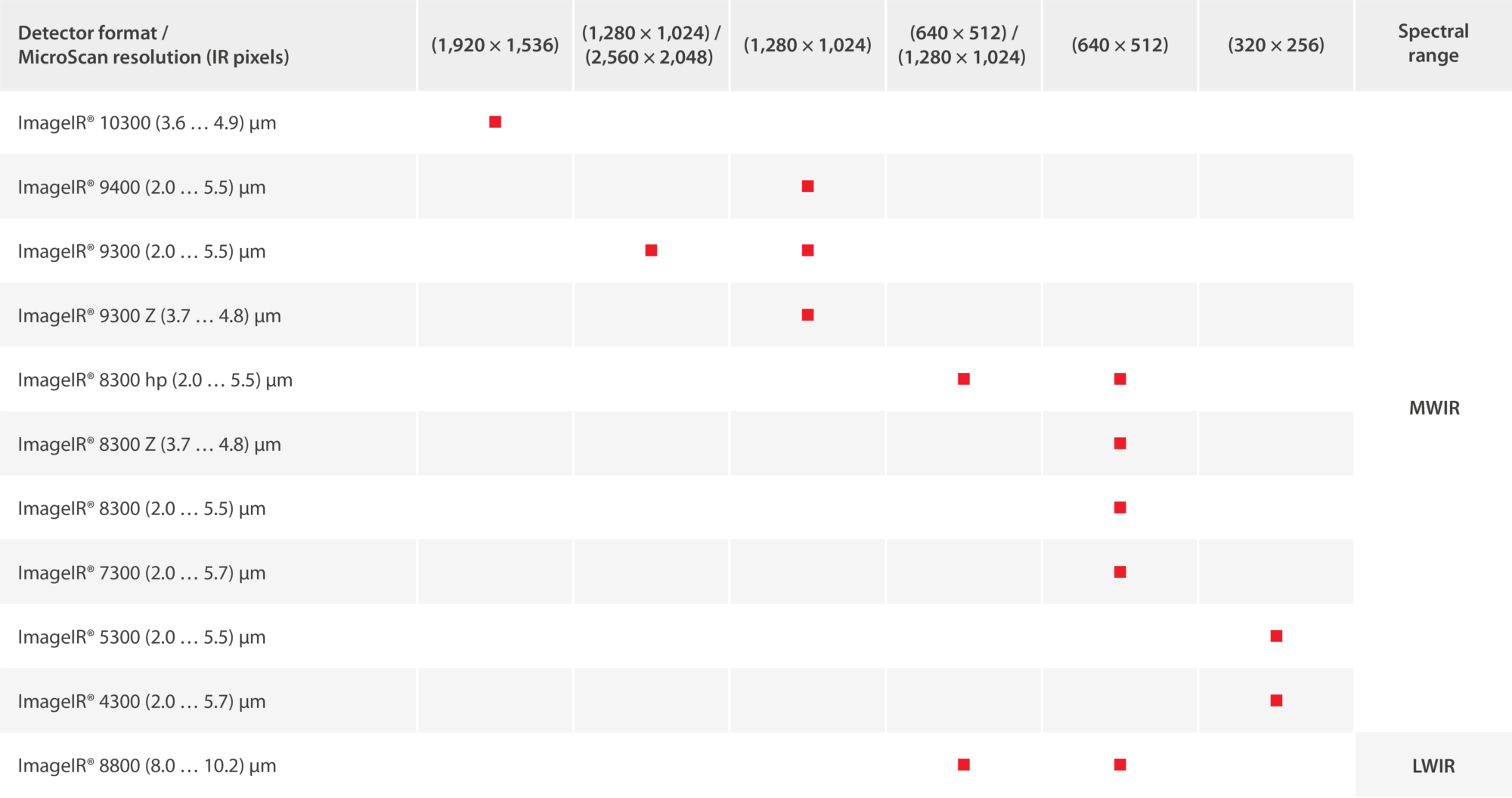

As the top model of this series the ImageIR® 10300 impresses with a cooled photon detector of (1,920 × 1,536) IR pixels being installed in an radiometric infrared camera for civil use for the first time. The transmission of the recordings in full hd achieves, thanks to the 10 GigE interface, frequencies up to 100 Hz in full frame mode.

For reliable detection of very small objects over extremely high distances the models ImageIR® 8300 Z and ImageIR® 9300 Z are available with a focal range of (28 … 850) mm. The ImageIR® 8300 hp in the format (640 × 512) IR pixels allows a full-frame rate of 350 Hz.

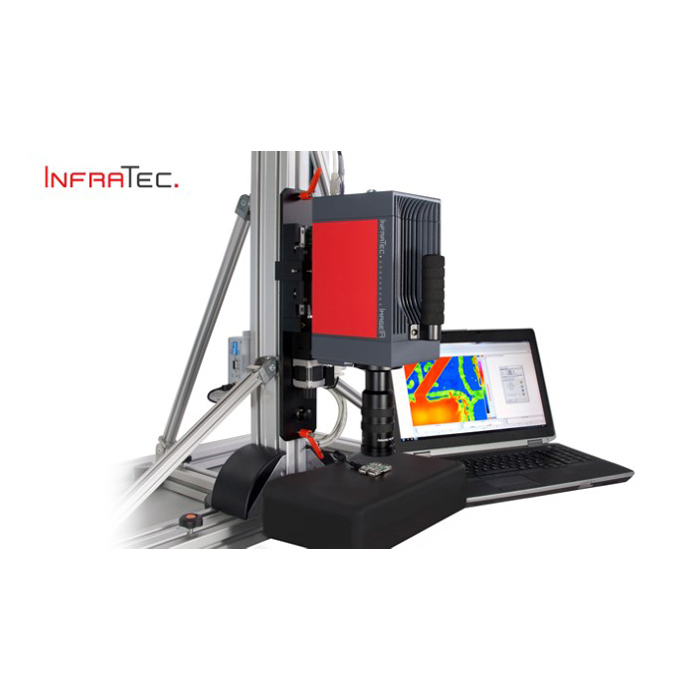

The series sets standards as an efficient high performance tool for thermographic investigations in combination with the thermography evaluation software IRBIS® 3.

Modular Device Concept

The modular device concept allows for an individual, customised equipment and utilisation in nearly all specialist fields.

- Aerospace technology, automotive technology, medical technology, laser technology, welding technology

- Electronics/microelectronics

- Glass-, plastic- and steel industry

- Research and development, non-destructive material testing

- Active thermography, Lock-in and spectral thermography, stress analysis

- Module testing, micro thermography

- Quality assurance for bonding techniques and blowhole reduction

- High-speed thermography, measurements of fast rotating objects in linescan mode (brakes and clutches)

- Object monitoring

- Airborne thermography