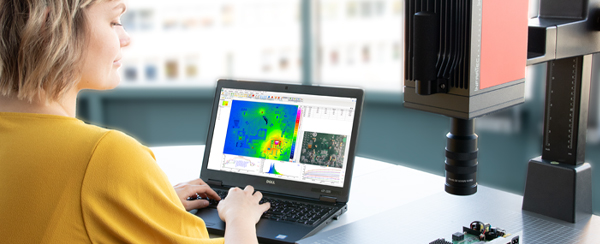

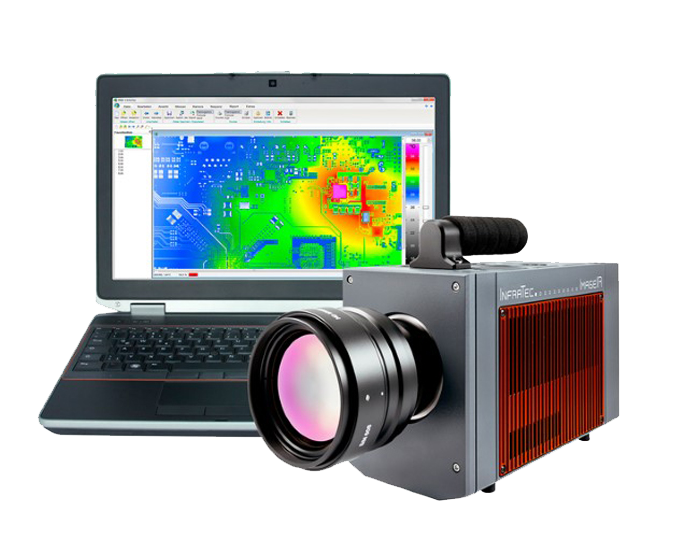

A high-quality infrared camera is the basis for successfully using infrared thermography to solve your measurement and testing tasks. However, the full potential can only be achieved with an equally powerful software. The result of Infratech’s R&D and hard work is their modular software family IRBIS® 3. Its range of functions can be configured to suit your application, so that the ideal package is available to you.

- Modular concept for application-specific configuration

- Compatibility with all camera models by InfraTec

- Convenient camera control and data acquisition

- Numerous analysis functions and tools

- Lock-in mode for the analysis of amplitude and phase images and other complex evaluations

- Consistent visual display of all measurement data

- Professional compiling of thermographic reports

VIC Edu

VIC Edu