After our recent partnership announcement with IO Industries we highlight the top 5 uses for their High Resolution camera range. As is the case with all applications, get in contact with us if you have a specific need and we will work to find a turn-key solution to match.

1. Weapons Range Testing and Tracking

A range of the IO Industries high resolution cameras has already been proven in this field. The global shutter CMOS sensors are a huge advantage when looking at test range tracking, this sensor ensures that blur doesn’t occur for fast moving objects giving a cleaner and clearer image. The ability to pair the high resolution cameras with quality DVR’s such as the IO Industries Core range, means that the testing can also provide a large amount of full-quality uncompressed footage. This footage can also be timestamped with appropriate range timings. The packages of high resolution cameras and digital video recorders are currently in use throughout the globe on a number of land, sea and air test ranges.

2. Production Line Troubleshooting

Where a combination of high resolution and high speed is required to troubleshoot production line issues, the IO Industries high resolution cameras are a perfect fit. The compact cameras are capable of being placed in close to factory machinery. When paired with the Core DVR’s, the cameras are capable of long record times which may be required to find faults. The range of CoaXPress outputs mean that there is quality footage of high resolution constantly being fed back to the recorders which can be stored at a distance to prevent data loss in the instance of a fault. Fault detection can then be replayed on the factory floor to find and rectify the error. The high resolution is an extra benefit where the fault may be unknown, allowing for a wider field of view to be captured and examined.

3. Electronic Inspection

The higher resolution cameras (Victorem 5.1M, 8.9M & 12.0M & Flare 12M / 48M) in the IO Industries range provide a perfect solution for an electronic inspections camera. These can be used for:

- SPI: Solder Paste Inspection (PCB inspection before component placement)

- AOI: Automated Optical Inspection (PCB inspection after components are placed)

- LCD Inspection (check for proper pixel behavior)

The CoaXPress output provides a reliable, fast, point-to-point connection to frame grabber.

4. Sports Biomechanics

Traditional memory based cameras require the user to download footage between gathering data. This prevents accurate biomechanic data, as it does not capture the repeated actions which can affect movement. The IO Industries High resolution camera (or multiple) paired with a Core DVR allow data to be captured over and over without the need to stop and download the footage. Output files from the cameras can then be analysed by the appropriate 3rd party software.

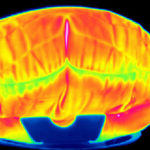

5. Medical Research

The high resolution cameras mean that more data is captured within the frame. This allows for a greater amount of analysis to be done and in turn, a better result in medical research. The IO Industries High Resolution camera range has already been used across the globe as a tool in in various medical imaging research tasks. On top of this, we see the potential in the detection and tracking of skin cancers. The high resolution of the cameras is also useful in optical research.

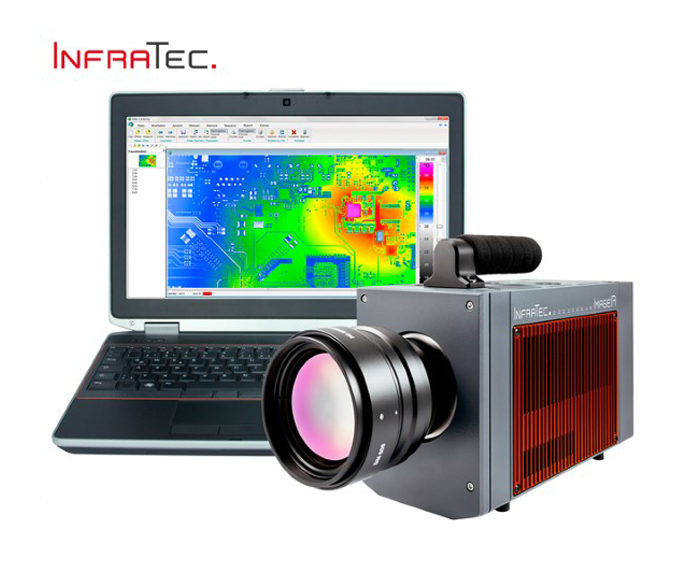

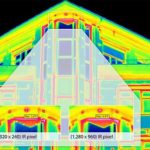

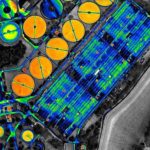

Active thermography is the induction of a heat flow by energetically exciting a test object. The heat and the flow of energy is then influenced by defects or material layers which makes it a great application for materiel testing. These inhomogeneities can be sen on the surface by high-precision infrared cameras such as our

Active thermography is the induction of a heat flow by energetically exciting a test object. The heat and the flow of energy is then influenced by defects or material layers which makes it a great application for materiel testing. These inhomogeneities can be sen on the surface by high-precision infrared cameras such as our

VIC Edu

VIC Edu