Efficient, Contactless Defect Detection with InfraTec’s TRC Thermography

Non-destructive testing (NDT) plays a vital role in ensuring product integrity, material quality, and process reliability across modern manufacturing. But traditional inspection methods can be time-consuming, require significant manual intervention, or fall short when it comes to detecting hidden defects in complex components.

InfraTec’s TRC (Thermal Resistance Coefficient) technology offers a highly efficient, contactless solution for detecting defects beneath the surface providing clear, actionable insights with minimal setup.

What is TRC Technology?

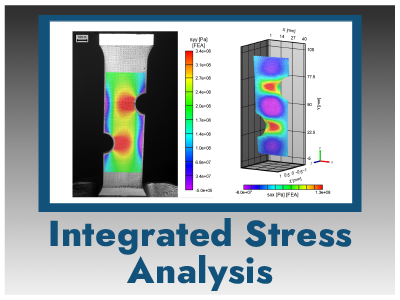

TRC-based thermography is an advanced inspection method that uses controlled thermal excitation to reveal subsurface flaws and inconsistencies in materials. By applying heat to a component and precisely measuring the resulting temperature response, TRC identifies variations in thermal conductivity that indicate defects such as:

- Inhomogeneities

- Voids or air pockets

- Delaminations

- Material thinning

- Adhesion problems

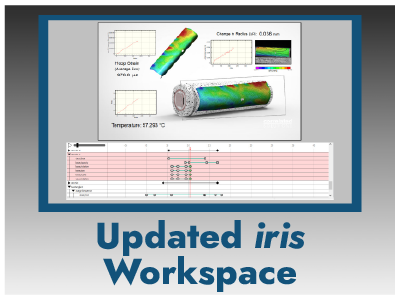

The system is non-contact, rapid, and ideal for use on components with complex geometries or sensitive surfaces.

Key Advantages of TRC for Non-Destructive Testing

- Contactless and Non-Invasive – No physical contact with the part is required, making TRC ideal for delicate or finished surfaces.

- Fast, Full-Surface Inspection – Entire areas can be tested quickly, providing an immediate overview of potential defects without needing point-by-point measurements.

- High Spatial Resolution – TRC detects even small or shallow subsurface defects, making it suitable for demanding industrial quality control processes.

- Applicable to a Wide Range of Materials – Ideal for plastics, composites, bonded structures, and other modern engineering materials commonly found in industrial manufacturing.

Where is TRC Used?

While TRC is versatile across many industries, its greatest impact is in manufacturing environments where precision, repeatability, and efficiency are essential. Typical applications include:

- Plastics Industry: Inspect moulded components for hidden air inclusions or uneven wall thickness.

- Composite Material Manufacturing: Detect bonding defects, delaminations, or inhomogeneities in layered structures.

- Bonded Structures: Validate adhesive joints and connections in lightweight assemblies.

- Quality Control of Complex Components: Quickly assess parts with irregular shapes or sensitive surfaces that would be difficult to inspect using conventional methods.

Supporting Process Reliability and Product Quality

Manufacturers are under constant pressure to improve product quality, reduce waste, and maintain reliable production processes. TRC technology supports these goals by providing:

- Quick, repeatable defect detection

- Reduced reliance on destructive testing or lengthy manual inspections

- Reliable process monitoring and quality control for both production lines and laboratory environments

Conclusion

As components become more complex and production processes demand higher precision, reliable and efficient non-destructive testing is essential. InfraTec’s TRC technology provides manufacturers with a practical, contactless solution for identifying subsurface defects helping to safeguard product quality and improve process reliability.

At Blink Technology, we supply advanced infrared inspection systems like TRC to meet the evolving needs of Australia’s manufacturing sector.

Interested in learning how TRC thermography could enhance your production quality?

Contact us today to discuss your application or request a product demonstration.

VIC Edu

VIC Edu