Real time measurement of strain and deformation can be a valuable asset and is available through Vic-Gauge real time processing. The below is a real case study of how Vic-Gauge was used, as part of a solution generated by Correlated Solutions to measure real time strain.

Key Objectives of DIC Project

- –Measure real-time strains and deformations of flexible sheets

- –Real-time analog output for strain and displacement measurement to control test

Challenges

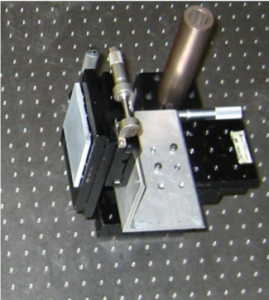

- For single camera, several key requirements

- Minimise the out-of-plane movement

- Maintain nominal planarity of specimen surface

- Keep sensor plane nominally parallel to specimen surface

Advantages of DIC Measurement System

- Full-field deformations throughout experiment

- Both quasi-static and dynamic loading measurable

Careful positioning and orientation of the DIC camera is crucial for most accurate measurements

- Correct orientation is readily achieved with carpenter’s square or laser pointer and a small mirror attached to specimen holder.

Minimize the error from any out-of-plane specimen movement by increasing distance from camera to the specimen

- Increased lighting intensity necessary for this situation

Key Points

- Test can be controlled using output analog signal from Vic-Gauge

- Large or small deformations are measurable