Thermographic Analysis of a Fusion Plant

What will the energy supply of the future look like? The Max Planck Institute for Plasma Physics (IPP) in Greifswald is dealing with this question.

In accordance with the weightily initial question, the researchers can draw on an impressive research instrument. “Wendelstein 7-X is the world’s largest stellarator-type nuclear fusion facility,” says Dr. Marcin W. Jakubowski from Stellarator Edge and Divertor Physics Department at IPP. “It is intended to show whether this construction type is suitable as a permanently operated power plant.” The aim is to achieve plasma discharges lasting up to 30 minutes with this plant, in other words, half an hour of continuous operation. This would be an important preliminary work on the way to a form of energy production that does not require fossil fuels such as oil, coal and gas, does not produce CO2 emissions and does not further promote global warming. During the second experimental campaign, which ended in October 2018, discharges lasting up to 100 seconds were achieved. This is considered a world record for a fusion facility of this type.

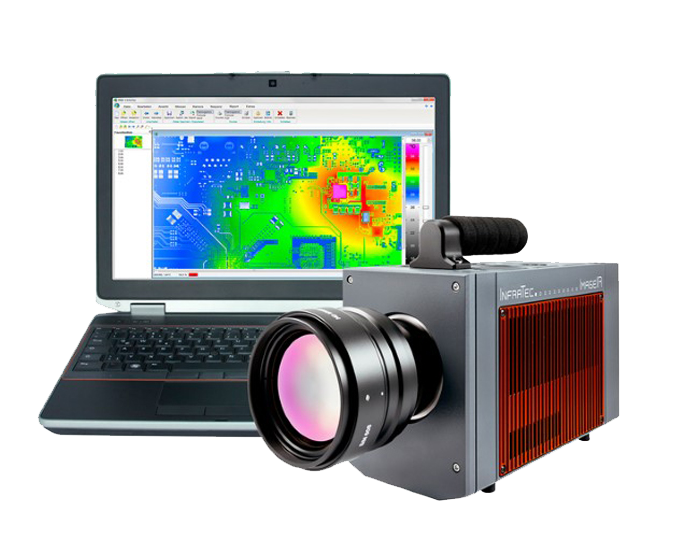

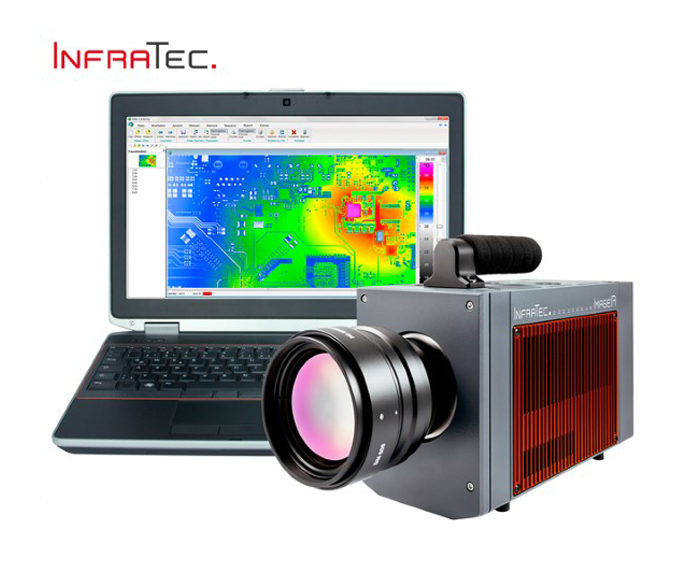

Use of the High-end ImageIR® 9300 Camera Secures Operation of the Fusion System

The scientists measure temperatures of up to 1,000 °C on the surface of the graphite tiles. In exceptional cases and locally very limited, up to 2,000 °C are registered. “Temperatures of more than 1,200 degrees Celsius are critical,” explains Dr. Marcin W. Jakubowski. “If this happens, the divertor can be damaged and tile elements can come loose.” If this were to happen, the system would have to be stopped and the divertor repaired. The consequence would be a forced break of at least six months.

Active thermography is the induction of a heat flow by energetically exciting a test object. The heat and the flow of energy is then influenced by defects or material layers which makes it a great application for materiel testing. These inhomogeneities can be sen on the surface by high-precision infrared cameras such as our

Active thermography is the induction of a heat flow by energetically exciting a test object. The heat and the flow of energy is then influenced by defects or material layers which makes it a great application for materiel testing. These inhomogeneities can be sen on the surface by high-precision infrared cameras such as our

VIC Edu

VIC Edu